Faster, Further, Smarter. We are the enablers of greatness.

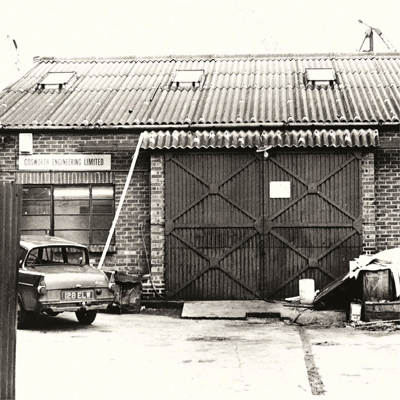

For 6 decades we have existed to innovate, push boundaries and take the propulsion industry to new heights. Founded in 1958 by Keith Duckworth and Mike Costin, a couple of young mavericks, they made race engines our livelihood for many decades. Culminating in one of the most successful engines in history, the DFV. As we grew bigger, we diversified, building engines for rally cars and eventually putting our name on a high-performance icon, our first production engine, the YB. Fast forward to today and we are still synonymous with high-performance innovation, we have grown our offering to a state that encompasses all forms of propulsion technology: batteries, alternative fuels, data and control systems, aerospace and marine engines.

For the last 65 years Cosworth has continued to deliver firsts on the racetrack and the road, as they have since 1958, when Mike Costin and Keith Duckworth formed their new company to “make a living messing around with racing engines.”

Cosworth launches first engine for Formula Junior one year after opening. The engine was one of the first to break 100hp per litre and claimed its first victory one year later.

With close ties to Lotus, Cosworth begin work on their Twin Cam engine, preparing it for competition use under the code TA. The engine proved to be very successful and won races in the hands of multiple drivers, including Jim Clark.

Cosworth enters the mass production road market with the BDA, developed for use by Ford in their Escort road and rally cars. Variants of the engine went on to great success in Formula 2 and Formula Atlantic.

Cosworth launches the DFX, a turbo-charged version of the DFV into the U.S, where it won ten consecutive Indy 500 races and dominated the series for a decade.

In 1984, Cosworth launch the WAA engine for the Mercedes’ 190E, Cosworth’s largest mass-produced engine of the time. A year later, the legendary Cosworth YBB hits the road, in the new Ford Sierra RS Cosworth.

Cosworth’s present-day electronics division is founded by Cambridge University researcher, Tony Purnell under the name Pi Research.

Cosworth launches the XB engine, an all-new design built both in the UK and USA, leading to Nigel Mansell taking the IndyCar Drivers Championship that year.

Cosworth continues its history of innovative firsts with VIDS1. Revolutionary technology for synchronising video with logged data allowing easy cross-referencing of how car and driver are performing on the track.

Cosworth becomes the sole engine supplier for the Champ Car World Series with Cosworth Electronics supplying the complete set of car electronics to both Champ Car and the IRL IndyCar series.

With the US Navy in need of a high performance, fuel efficient propulsion solution for its jet fuelled UAVs, Cosworth developed the AG2, a ‘flat’ twin engine with unrivalled fuel efficiency and durability.

Cosworth begins exclusive delivery of custom scrutineering for the Intercontinental Le Mans Cup (now the WEC) and a new 4G telemetry system, Live on Air™ provides a dedicated network for the IndyCar series.

Cosworth opens its new state-of-the-art flexible manufacturing facility. The Advanced Manufacturing Centre delivers OEM style production capabilities for high-performance engines and premium vehicles.

Cosworth launch PDR (Performance Data Recorder) with Corvette, a development born of Cosworth’s long-term partnership with the Corvette Racing team.

Cosworth develops gasoline engine technology to yield lower CO2 emissions with its 2.0-litre passenger car engine. The design minimised frictional and pumping losses to keep efficiency high.

Working as part of a UK consortium, Cosworth uses its expertise in the Multi-Car Collision Avoidance project (MuCCA), aimed at improving operation and safety of autonomous and connected vehicles.

Cosworth selected to develop the new Aston Martin Valkyrie 6.5-litre naturally aspirated V12 hypercar engine, poised to redefine the limits of road car performance.

Cosworth becomes the official supplier of BTCC’s hybrid element, all cars on the grid are using this technology. Development commenced in 2019 ahead of the 2022 season.

Cosworth develops the world’s first Engine Control Unit with 200kHz Cylinder Pressure Monitoring with the ability of logging eight cylinders.

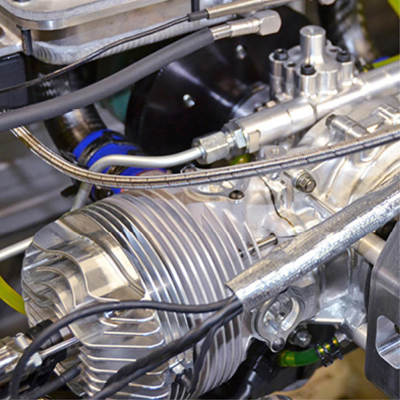

Cosworth partners with GMA to develop and produce the 3.9-litre V12 engine that powers the T.50 supercar. The incredible engine revs to 12,100 rpm, making it the highest revving production car engine in history.

Cosworth acquires Silverstone-based electrification and vehicle development specialists, Delta Motorsport, to accelerate the drive to a sustainable future.

The partnership with GMA continues, leading to the development of the naturally aspirated 3.9-litre V12 engine to power the T.50s Niki Lauda track-focused supercar.

GMA launches the T.33 a two-seat super car, the design is heavily influenced by Gordon’s interest in 60s sports cars. The car is powered by a reworked version of the 3.9 litre Cosworth V12 found in the T.50 and T.50s.

At Cosworth, our aim is to enable and inspire our customers to push the boundaries and create vehicle experiences that are smarter, cleaner, go faster and further. We are a group of like-minded people, united by our passion for engineering, our ‘out of the box’ thinking and commitment to delivery.

Purpose: Passionately pushing the boundaries of high-performing vehicle technologies.

Vision: To be a trusted partner, engineering the best integrated vehicle technologies to enable our customers to succeed in an ever-changing world.

As we all look to protect the future of our planet, we are actively taking steps to implement more ways in which we can reduce our impact and positively support the environment. From helping our customers develop cleaner solutions to minimising the resources required to produce our products and maximising what we re-use or recycle we are always looking to expand on our existing commitments.

Read more about the way we operate with our environmental policy.

When you’re looking to push the boundaries of what is achievable within vehicle engineering, there is need to continuously look at new ways of doing things. So, that’s exactly what we do using our dedicated research and development teams.