Cosworth has joined forces with Cambridge Vacuum Engineering (CVE) and TWI to design, build and test an electron beam welding machine that hopes to optimise the manufacturing of battery packs.

Cosworth has joined forces with Cambridge Vacuum Engineering (CVE) and TWI to design, build and test an electron beam welding machine that hopes to optimise the manufacturing of battery packs.

The EB-Bat project will be funded by Innovate UK, under the Faraday Battery Challenge. The Faraday Battery Challenge is a partnership between Innovate UK, UK Battery Industrialisation Centre, and The Faraday Institution to support the research and development of the most promising, innovative, and sustainable battery technologies for the propulsion of electric vehicles in the automotive sector. £27.6 million of funding is being invested across 17 research and innovation projects and facilities that will drive the growth of a strong battery business in the UK.

The use of electron beam welding is set to be 20 times faster than laser welding, and is not impacted by the reflectivity from copper and aluminium, allowing for more reliable and consistent welds. Other benefits of electron beam welding include energy savings, a smaller factory footprint, a reduction in scrap material and welding fume control.

The EB-Bat project will provide a compelling demonstration of the process performance, productivity, quality, and economics to the automotive manufacturing sector with an aim to secure funding to take it into production.

The project partners bring together a wealth of experience in the automotive industry, with TWI as a world-leading welding and materials development organisation and CVE, designers and manufacturers of electron beam and laser welding machines for many applications, including turbochargers.

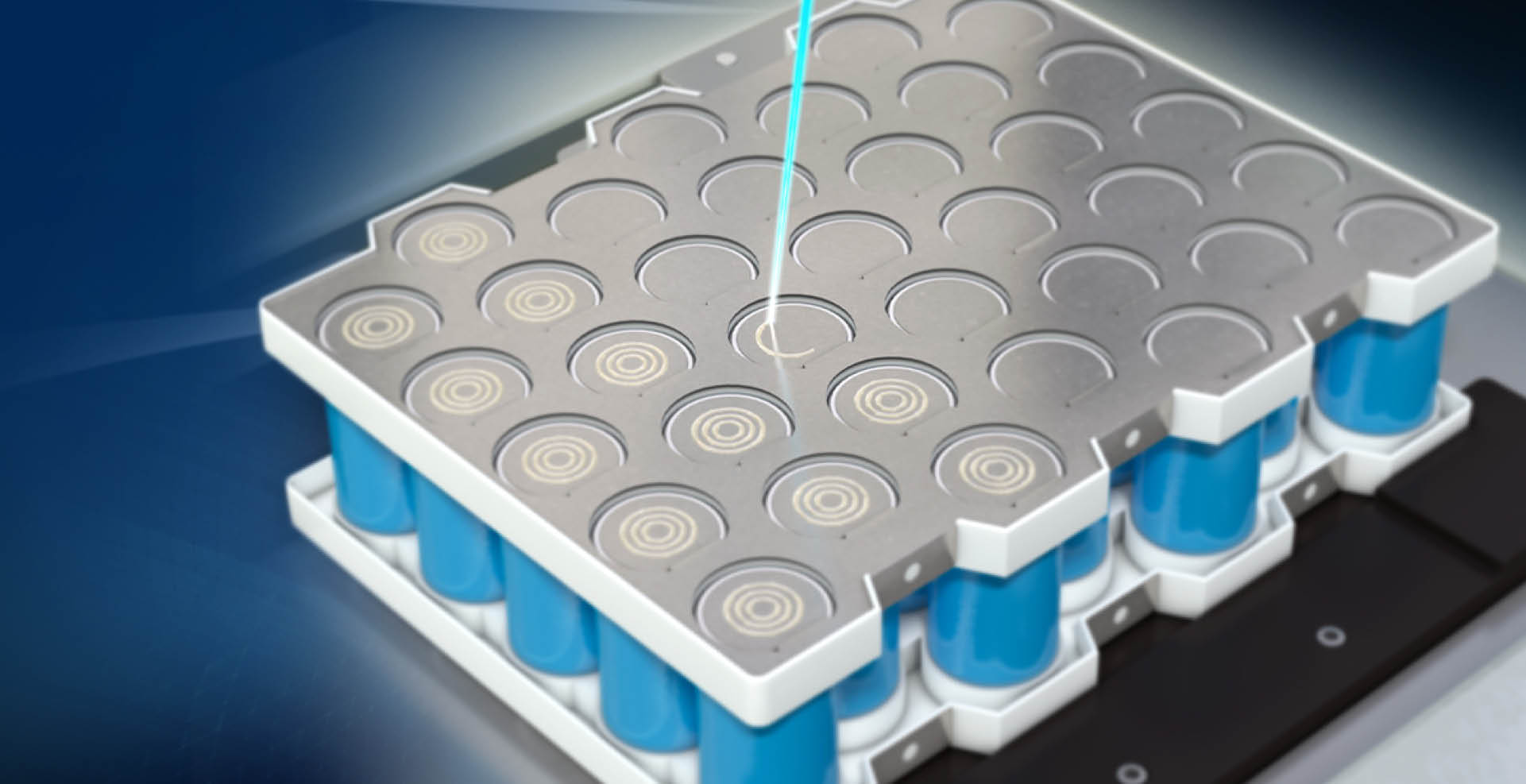

Developing and manufacturing flexible battery solutions is one of Cosworth’s core capabilities, the Cylindrical Scalable Modules is a prime example of this. The electron beam welding offers a more efficient and reliable way to manufacture batteries, maximising the battery technology’s potential and the new manufacturing techniques can be transferred across the wider Cosworth Group.