Transforming Touring Car Racing with Our Award-Winning Hybrid Solution

Cosworth's groundbreaking hybrid system, now entering its 3rd year with the British Touring Car Championship (BTCC), marks a significant milestone as the first touring car series to integrate hybrid technology. TOCA's decision to embrace hybridisation reflects a forward-looking approach to sustainability in motorsport, and Cosworth was entrusted with the task of developing and delivering an innovative solution.

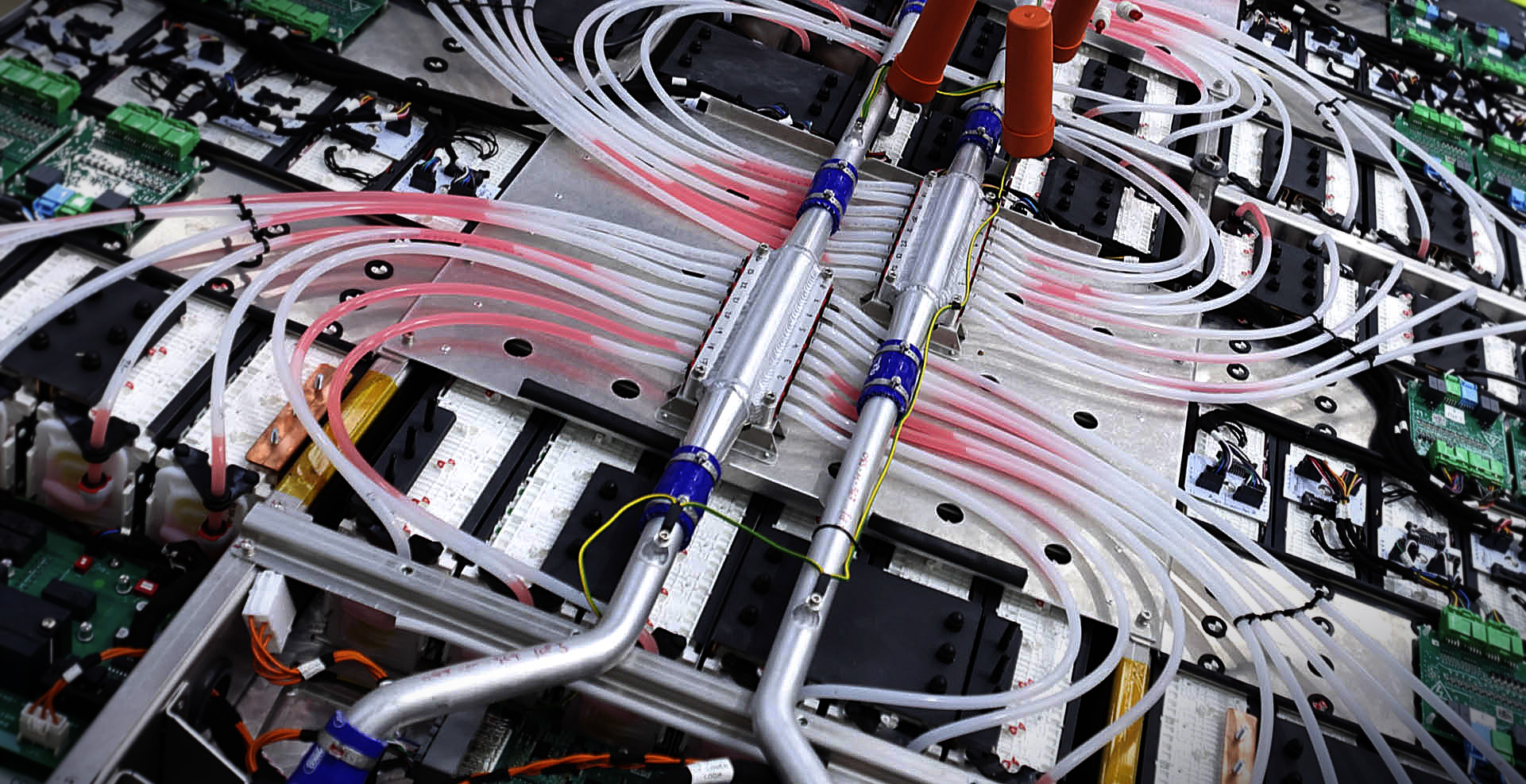

Our fully integrated hybrid package, comprising a 48v battery, motor controller, motor generator unit, and dual cooling systems, embodies our commitment to excellence. Drawing on our extensive expertise in both motorsport and automotive industries, this solution was meticulously crafted across our Cottenham and Silverstone facilities, ensuring the highest standards of quality and performance.

As pioneers in eco-friendly racing technology, we're proud to lead the charge in transforming touring car racing towards a more sustainable future.

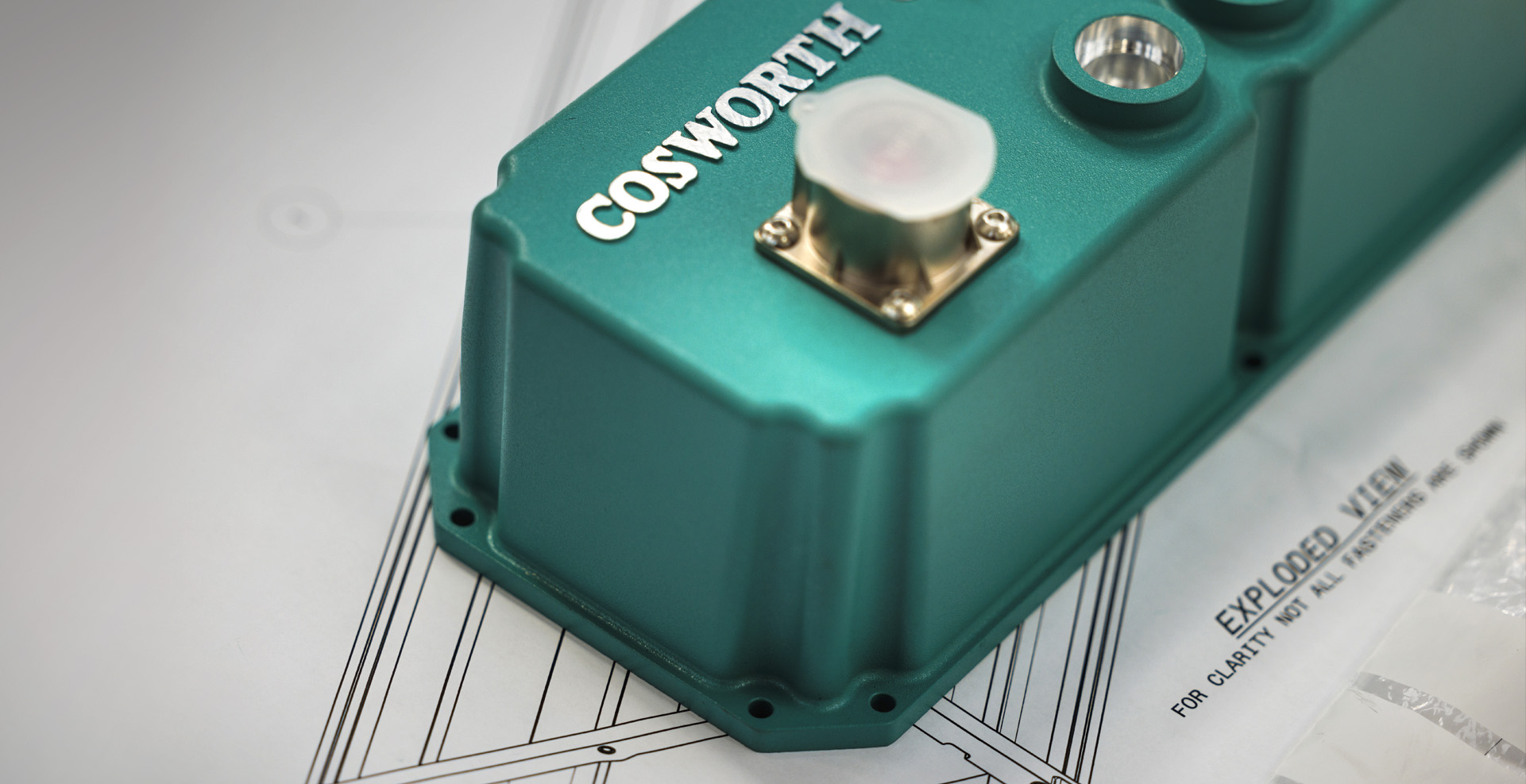

Our Antares 8 VCU (Vehicle Control Unit) has the capabilities to drive the entire hybrid package, from running the ICE to managing the control strategies for all the hybrid powertrain components. On top of this, Antares 8 facilitates full chassis and ICE data logging. Powertrain strategies can be written suing an array pf pre-existing software and provide control for FBW: and ICE strategies, Energy deployment, Energy regeneration, Cooling systems, Safety parameter protocols.

The 48V battery pack is our advanced energy store for the hybrid system. It includes a 12V charging connection and BMS (Battery Management System). The package is self-isolating on disconnection from the car and when the vehicle charger is disconnected.

The Delta Cosworth BMS monitors battery cell health and the energy control for deployment and regeneration. It also has the responsibility for sending and receiving of all battery related data. Lastly, it manages the control strategies send from the Antares 8 VCU, these strategies are calculated as a result of the data received from the BMS itself.

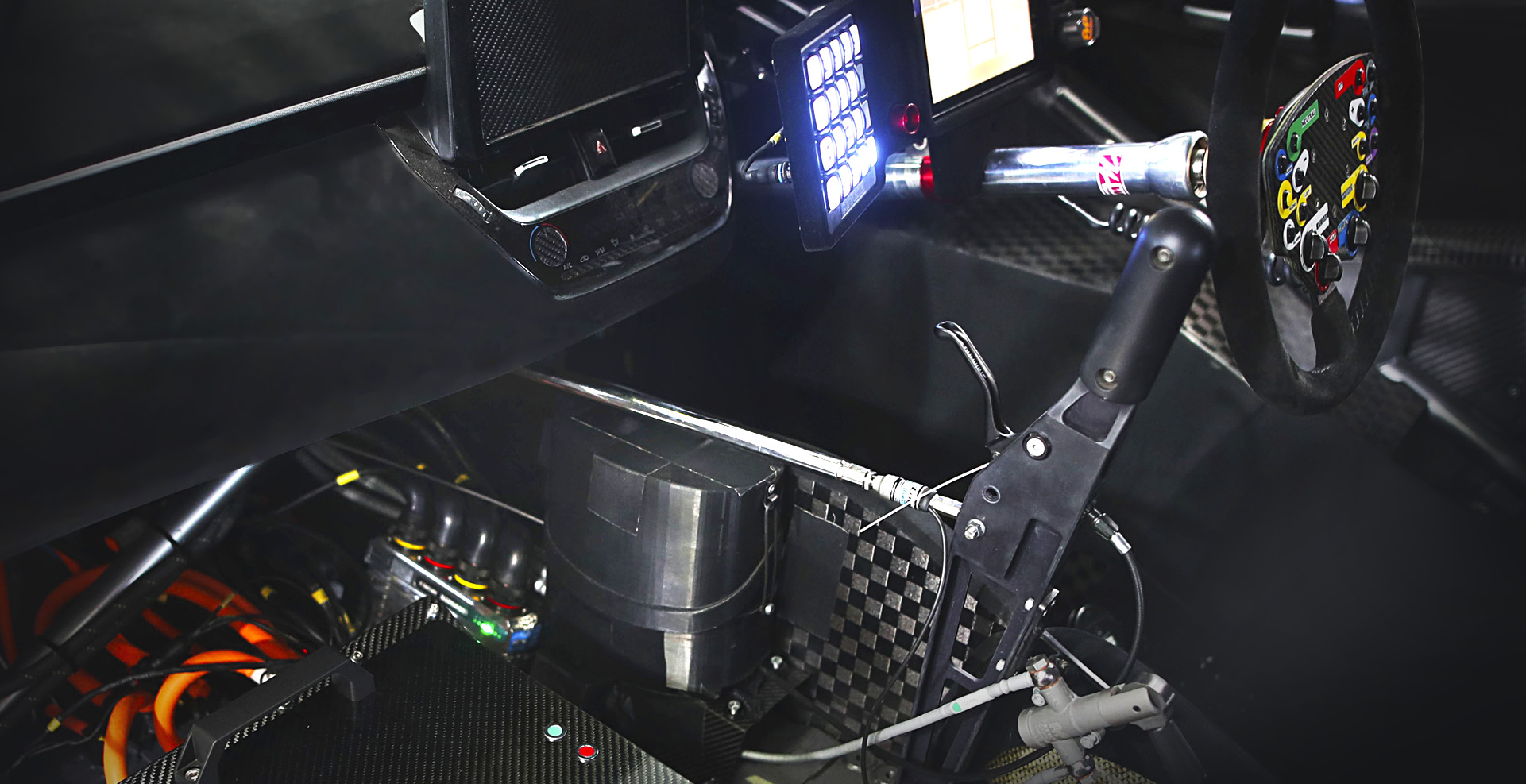

The P2 off-axis electric motor (known as the MGU) is connected to the powertrain through the championships spec gearbox and is used to deploy and regenerate energy stored in the battery pack. The unit is managed by a dedicated motor controller package and is capable of producing 30kW (=40hp) of peak power.

The dedicated motor controller communicates the energy and regeneration strategies to and from the electric motor. The unit also manages the energy flow to and from the battery pack. Deployment and regeneration are controlled by the Antares 8 VCU, including motor speed, torque monitoring and energy deployment from the electric motor.

We provide custom designed PWR cooling systems for both battery and motor to ensure they are kept within the correct operating temperature parameters. The custom radiators dedicated to the hybrid system components manage cooling for: MGU (Motor Generator Unit), Inverter/ Motor controller, Battery pack.

Temperature sensors and coolant pressure pumps report back to the Antares 8 VCU. In turn, control strategies are communicated to electric coolant pumps to safely manage system temperatures and pressures.

There are few events that can consider themselves as iconic or exciting as the Goodwood Festival of Speed and its legendary hill climb.