Developing high-performance engines has been the backbone of Cosworth since the company’s inception

Whether on land, sea or air hybridisation forms an important part of our electrification offering.

Our state-of-the-art manufacturing facility at Silverstone is ISO 9001 certified

Our Catalytic Generator, is a 35Kw zero emission capable, compact, and lightweight generator

Electrification is now a key pillar of the propulsion industry. We are excited to be playing a leadi

We are a crucial part of wind tunnel development for Formula 1 teams and OEMs

Embark on a journey with Cosworth’s AliveDrive. A versatile ecosystem carefully designed to facilita

From ground-breaking piston technology to bespoke hybrid systems

We strive to deliver diverse, efficient solutions, from ICEs to electric powertrains

We have a range of propulsion and control solutions from ICE to EV powertrains

With our engineering excellence we can offer some of the most efficient, high-performance solutions

Cosworth’s DNA was born from motorsport

Today, we produce some of the most advanced electronics for teams and championships across the globe

With our extensive capabilities, we possess the ability to develop all subsystems of a vehicle

As part of our total race electronics our support engineers are on hand to help troubleshoot

Cosworth service product returns

The Antares range of ECUs are highly-developed control platforms featuring multiple FPGAs and proces

We are continually developing our offerings across the board

Nurturing young engineering talent is a core part of Cosworth’s values

We’re on the search for the brightest minds that can solve problems and are up for a challenge

Interested in working with us?

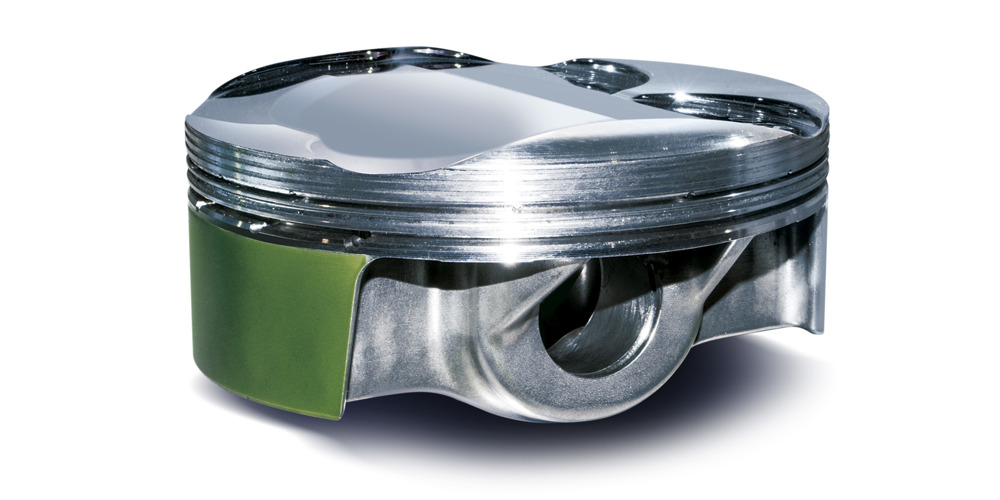

We produce over 40,000 forgings and 20,000 fully machined pistons p.a. to our customers’ designs. In our dedicated piston facility, our pistons are made to the highest quality levels (and often to tight deadlines) from forgings, machined billet 2618, 4032 or MMC.

From full clean sheet design, to engineering, testing and validation – we support the full piston development cycle. Our reciprocating component design process ensures that piston and con rod designs work in harmony. Honing our expertise in engineering using the latest in 3D technology allow us to refine and improve on existing designs.

Our pistons are utilised in a huge variety of different forms of motorsport. From the highest level of international car and motorcycle racing to historic and club level motorsport, our piston customers have won countless races and championships.

Additionally, we work with major OEM customers designing and manufacturing pre-production prototype pistons in a variety of batch sizes. Typically these pistons are machined from billet to allow rapid testing of alternative skirt profiles, crown designs and other features.

With full traceability from raw material to finished piston, every Cosworth piston is produced to the highest quality and then laser etched for ease of identification. We rigorously adhere to ISO9001 and AS9100 quality standard and operate a fully audited supply chain. We also offer NDT and CMM inspection in-house.

Please Contact for further information.

Cosworth empowers organisations to reach their full potential with innovative solutions and world-class products and services that enhance performance and enable greatness.

The Octagon, St James Mill Road

Northampton, NN5 5RA, UK

Brookfield Technology Centre,

Twentypence Road, Cottenham,

Cambridge, CB24 8PS, UK

5355 W 86th St,

Indianapolis, IN,

46268, USA

Unit 9, Silverstone Technology Park

Silverstone Circuit,

Northants, NN12 8GX, UK